Consultation, Conceptualization, & Program Management

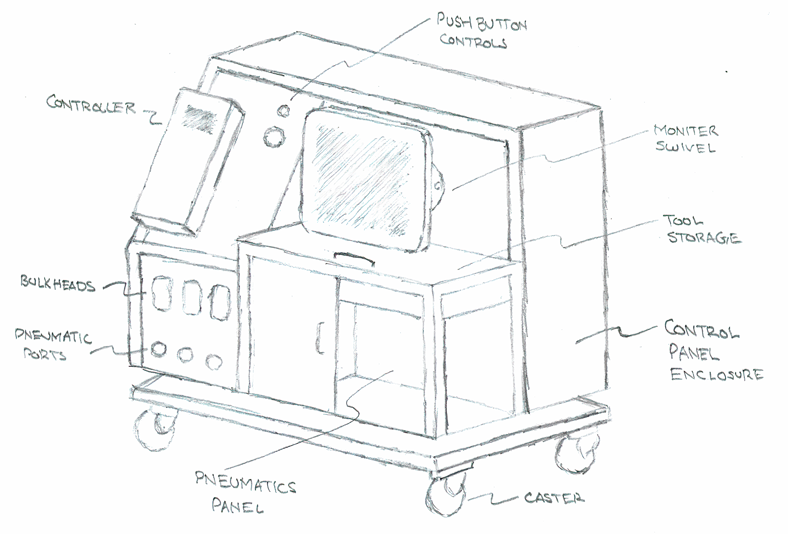

• We work with clients to identify their needs and provide block diagrams and sketches to clearly define the solution and our scope of work

• We have developed a highly responsive culture that is dedicated to continual improvement and meeting all customer requirements through effective customer communication and project execution

• Our day-to-day project management ensures our clients are always up-to-date and keeps our projects on-schedule and on-budget

Electrical & Mechanical Engineering

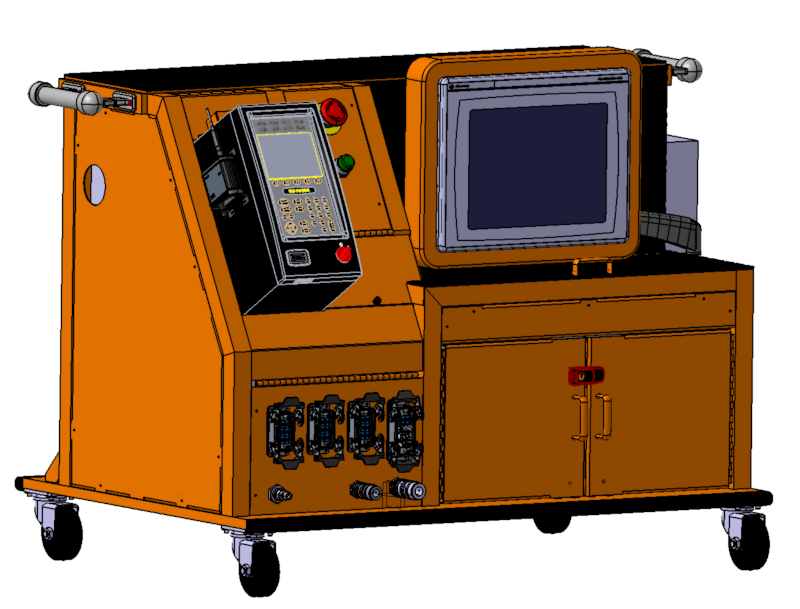

• Our teams, led by licensed Professional Engineers (PE), develop calculations and analyses, 3D models, CAD schematics, bills of material (BOM), specifications, installation and safety plans, and other documents as part of our drawing package

• Electrical and Mechaninal Engineers work together, in parallel, to design seamless solutions

• Mechanical Engineering Services include: CATIA V5 & Solidworks modelling; Finite Element Analysis (FEA); vibration and thermal analysis and mitigation; structural design

• Electrical Engineering Services include: Closed servo loop performance and analysis; PLC based control systems, Supervisory Control and Data Acquisition (SCADA) systems; robotic solutions, machine vision integration

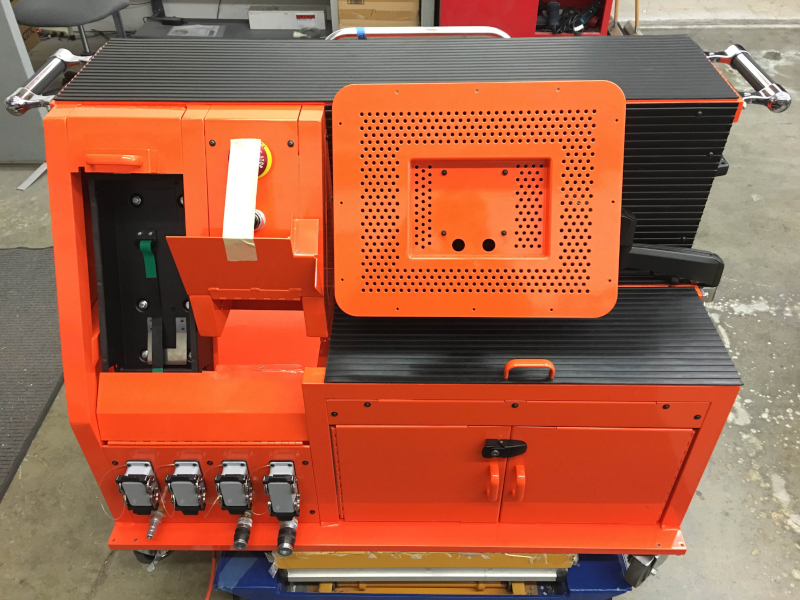

Electrical & Mechanical Equipment Fabrication

• Our planning travelers and procurement purchase order system ensures a well documented and fully traceable manufacturing process

• Assembly and wiring of electrical control panels to UL 508A Standard and final assembly to NFPA 70 and NFPA 79 Standards

• Dimensional checks on all critical fabricated components

• We have excellent working relationships with major design firms and fabrication facilities nationwide to support projects larger than our two shops (41’x29’x11’H & 34’x20’x9’)

Programming, Testing, & Documentation

• PLC and HMI programming of all major PLC brands including: Allen Bradley (Studio 5000), Siemens (TIA), Omron (Sysmac)

• Custom PC software development in major languages including: C#, C++, .NET

• 100% continuity and functional testing to verify equipment meets design inputs in accordance with test procedures with customer witness and reports

• In addition to the drawing package, we provide Operation, Maintenance, Programming manuals; troubleshooting guidelines, spare parts list, vendor contacts, and maintenance schedules

Customer Support

• Our team supports on-site installation, commissioning, and training operators and maintenance technicians

• We provide continued post-delivery consultation in addition to a 1 year product and service warranty

• Online/remote troubleshooting of fielded equipment through major platforms including: WebEx and Teamviewer

Custom Solutions with Off-the-Shelf Components

Hand in hand with our practical and theoretical knowledge of electrical engineering, programming, and codes and standards is a detailed understanding of electrical control and power processing devices, operating and programming software, and motion and machine controllers made by all major suppliers including Allen Bradley, Siemens, Square D, Cutler Hammer, Indramat, Idec, GE Fanuc, Keyence, and others.